2018-10-18

TERMA’S IMPRESSIVE MERCURIAL BEPICOLOMBO STORY

Terma is proud to be deeply involved in this exciting mission to Mercury, planned for launched on 20 October.

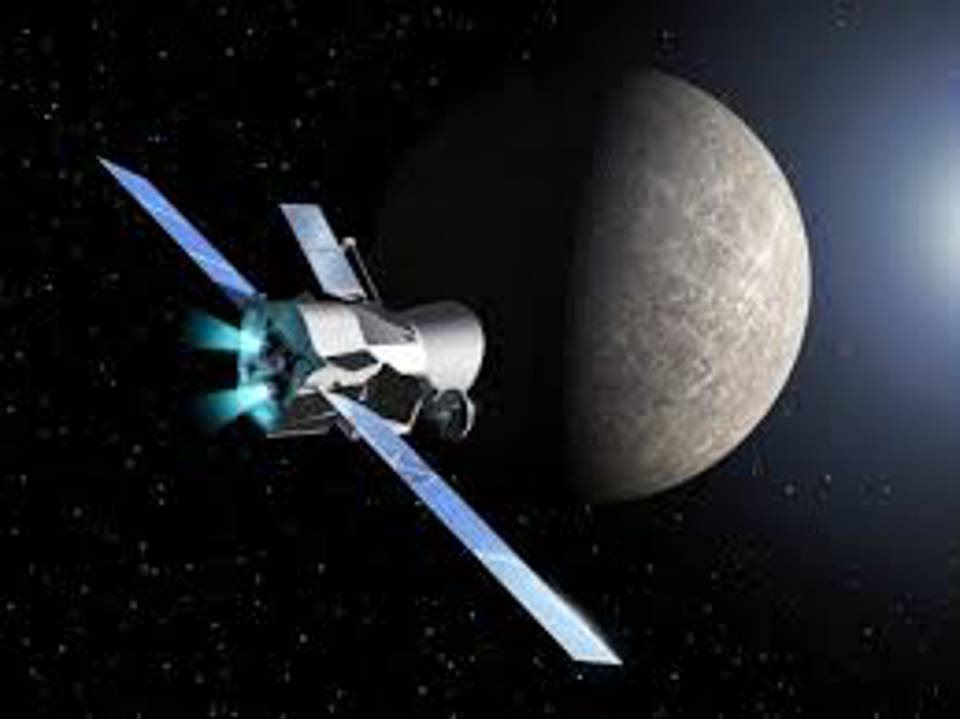

On 20 October at 03:45 CEST, the European Space Agency’s BepiColombo spacecraft is scheduled to be launched on an Ariane5 launcher from Kourou in French Guyana. It will be the start of a seven-year and nine billion kilometer flight to its final destination, in orbit around Mercury, the closest planet to the Sun.

BepiColombo, a collaboration between Europe and Japan, is one of the so-called ‘cornerstone’ missions of the European Space Agency and representing a major international investment into scientific research into Mercury and our Solar System, has been more than 20 years in planning and preparation.

The mission comprises three spacecraft travelling together to Mercury, the Japanese Mercury Magnetospheric Orbiter (MMO), the European Mercury Planetary Orbiter (MPO), and the transfer module Mercury Transfer Module (MTM). After arrival in 2025, the two scientific satellites will orbit Mercury.

Terma is proud to be deeply involved in critical hardware and software for this exciting and challenging project. We have been directly involved in the preparation of the mission for more than 15 years and will continue to be part of the mission operations during its flight to Mercury.

Major contributions by Terma include:

Terma provided the power unit for the MTM, the biggest and most advanced Power Conditioning and Distribution Unit (PCDU) developed by Terma, building on the success of power units provided for other interplanetary missions including comet chaser Rosetta and Mars and Venus orbiting spacecraft.

This high power unit provides the electrical power for the Mercury Transfer Module, including two ion propulsion thrusters that will drive BepiColombo to Mercury during the entire journey. In addition, it provides power for the MPO until arrival at Mercury.

BepiColombo PCDU undergoing tests in the Thermal Vacuum Chamber

The power distribution technology developed by Terma for this specific mission has formed the technological base for contracts on six similar advanced power units for four different European missions.

Terma also provided the Central Checkout System (CCS), used for testing the BepiColombo spacecraft subsystems during assembly and integration. Terma also provided software for the equipment used for testing the 12 instruments integrated on board BepiColombo. This software system is a commercial success today.

Terma is a key part of the industrial team that during 2011-13 developed the Mission Control System used by the spacecraft operators at the European Space Operations Centre (ESOC) in Darmstadt, Germany, for monitoring and controlling the BepiColombo spacecraft.

Since May, a dedicated team of three Terma staff members has been located at ESOC, providing support and participating in simulations in preparation of the launch campaign. This team will be part of the launch team during the three-day launch and early orbit phase.

Also located at ESOC are three Terma Flight Dynamics specialists, providing support for spacecraft maneuver optimization and test and validation of the flight dynamics software.

Finally, on console at ESOC performing spacecraft operations as part of the BepiColombo Flight Control Team will be Alkan Altay, Terma Attitude and Orbit Control System Operations Engineer.

Many of the 210 Terma employees involved in space activities have been in touch with the BepiColombo mission, and we keep our fingers crossed that all goes well with the start of this amazing journey.

See more at: http://sci.esa.int/bepicolombo/

Who we are

Terma in Brief

The Denmark based high-tech Terma Group develops products and systems for defense and non-defense security applications; including command and control systems, radar systems, self-protection systems for aircraft, space technology, and aerostructures for the aircraft industry.

Learn more about us