Precision and Reliability in Planetary Defense

It has little focus from the media. Few people realize it. But among the main threats to Earth and humankind are rogue asteroids. Asteroids that can easily destroy a city, or the mega-ones that can wipe out every living thing across the planet. It’s a serious threat, but fortunately, the European Space Agency and NASA are now taking up the fight and have invited Terma to join forces.

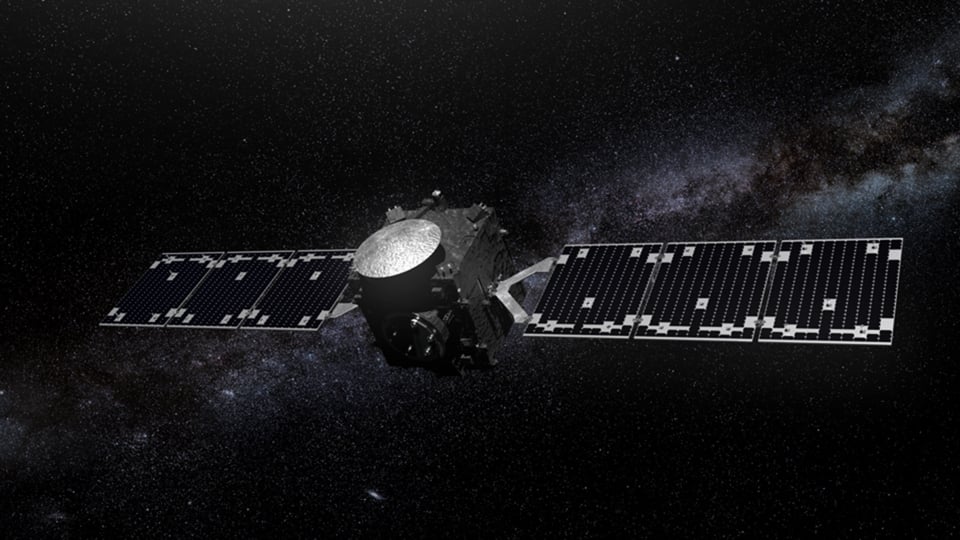

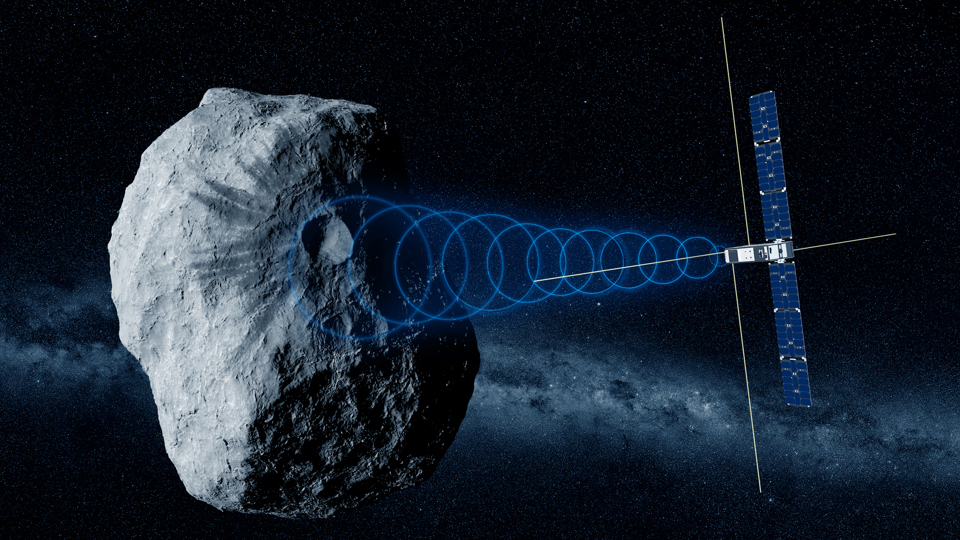

The European Space Agency’s HERA Mission represents a pivotal moment in planetary defense and advances our ability to protect Earth from asteroid threats. Building on the success of NASA's Double Asteroid Redirection Test (DART) mission, which impacted the asteroid moonlet Dimorphos, HERA will conduct a detailed post-impact study of the Didymos binary asteroid system. As Europe’s premier planetary defense initiative, this mission aims to refine asteroid deflection techniques while navigating the complex challenges of space operations in low-gravity environments.

Streamlining Control and Power Systems for Mission Success

Terma’s contributions ensure that HERA’s satellite systems operate with precision and reliability throughout the mission. By delivering advanced technology for system management, propulsion control, on-the-ground testing, Terma plays a vital role in enabling the spacecraft to perform its mission-critical tasks.

Our Remote Terminal Units (RTUs) ensure seamless management of in-flight satellite subsystems, while our innovative ground testing solutions ensure the spacecraft’s systems function efficiently and without unwelcome surprises during both the journey and the mission's demanding operations. With these technologies in place, HERA is well-equipped to fulfill its objective of enhancing planetary defense capabilities.

Terma’s Key Contributions to HERA

Data Handling SCOE

The DHS SCOE is used to test the onboard data handling system during the whole AIT sequence together with CCS5 & TSC for the central checkout system. Additionally, it supports the flight software development activity by providing an interface to load the flight software and monitor its execution. The following subsystems are verified using the SCOE: On-board Computer, Mass-Memory Unit, Remote Terminal Unit (Platform, Payload and Propulsion).

Remote Terminal Units (RTUs)

Two of Terma’s RTUs are integral to the satellite’s operations. The Platform RTU (6.0 kg) manages essential equipment and sensors, providing real-time data on satellite health and system status. The Chemical Propulsion System (CPS) RTU (8.7 kg) enables precise control of the spacecraft's 22 thrusters, ensuring accurate trajectory adjustments and fuel management. Both RTUs are designed with full redundancy, safeguarding mission continuity even in the event of system failure.

RF Suitcase

Terma provides a system for validation of the RF compatibility between the HERA spacecraft and all ground stations, which will support the HERA mission during its lifetime. It can serve also as a spacecraft simulator post-launch, which will support with understanding of spacecraft anomalies and avionics software behavior during the operational phase.

Power SCOE Systems

Terma’s Power Special Check-Out Equipment (SCOE), including the Battery System Simulator and Solar Array Simulator (BSS+SAS SCOE), plays a key role in testing the satellite’s power systems during construction and before launch.

RF SCOE

Terma provided a high performance qualified automated measurement test equipment. This system is used for testing and verification of the Spacecraft Communications Module in X-Band for Telemetry, Telecommand and Ranging subsystem.

Flight Software Development

Terma contributed to HERA’s flight software by delivering tools for monitoring execution, loading systems, and providing diagnostic interfaces to support mission-critical tasks.

Meeting the Challenges of Controlling a Satellite

Managing HERA’s complex satellite systems required innovative solutions. Terma’s Platform RTU powers and controls equipment based on commands from the on-board computer, continuously gathering data to monitor satellite health, including the operation of critical systems like the reaction wheels.

The Chemical Propulsion System RTU, with its millisecond precision, not only manages HERA’s propulsion with the 22 thrusters, it also oversees fuel valves and tracks temperatures and fuel levels to keep the satellite operational. Extensive testing in a range of conditions has ensured that these systems can perform reliably under the harsh realities of space travel.

Eco-Friendly Power Testing with UniverSAS

Efficiency and sustainability were core considerations in Terma’s approach to HERA’s Electrical Ground Support Equipment (EGSE). Terma’s UniverSAS—a versatile and compact power testing system—streamlined HERA’s power testing by combining the functionalities of a Battery System Simulator and a Solar Array Simulator into one unit. This all-in-one system supports testing with both source and sink capabilities and the option to recycle energy back into the mains, which reduces power consumption and minimizes heat generation, making the solution both energy-efficient and more eco-friendly.

Results: Reliable Operations and Increased Efficiency

Terma’s reliable solutions have simplified the spacecraft’s design, operations, reduced troubleshooting time and ensured that HERA can collect vital scientific data to ensure planetary defense through asteroid deflection.